Our Innovation

BAHU-BALLI [BSUSUPPORT]

We have developed a unique solution that combines bamboo and High Density Poly Ethylene (HDPE). nature of HDPE. HDPE is known to have a life of between 50 to 100 years. It is highly resistive to heat, light and water & other forces of nature. It also resistant to stress caused due to pulling, has good weight bearing ability & can bend to take the strain due to high winds, etc. This HDPE protects the encased bamboo material from rapid weathering, thus taking advantage of both the strength and tensile strength of bamboo and the rugged nature of HDPE.

Problems in BOUNDARY POLE

The current available poles for boundaries are unreliable and of poor quality, often giving way in a few years of usage leading to recurring cost of maintenance and replacement, not to mention losses incurred due to livestock & human interference. Poor quality means in 4-6 years the poles have to be replaced. This is because cement wears off & the iron bars start rusting. This is because there is no standard manufacturing practice around the same. We identified this need and have come up with a unique solution – that is an Industry First.

Problems in TRELLIS (support for plant climbers)

Currently, all farmers holding 0.25 acres to 300+ acres in India doing vegetable farming use bamboo or some local stick for the base support structure to build trellis support for climbing plants. The moisture in the soil and weathering causes this bamboo or wood to give away in a few years leading to the need to replace them. The non-standard shape & quality of existing solutions means the quality of the structure and the resultant crop also suffer.

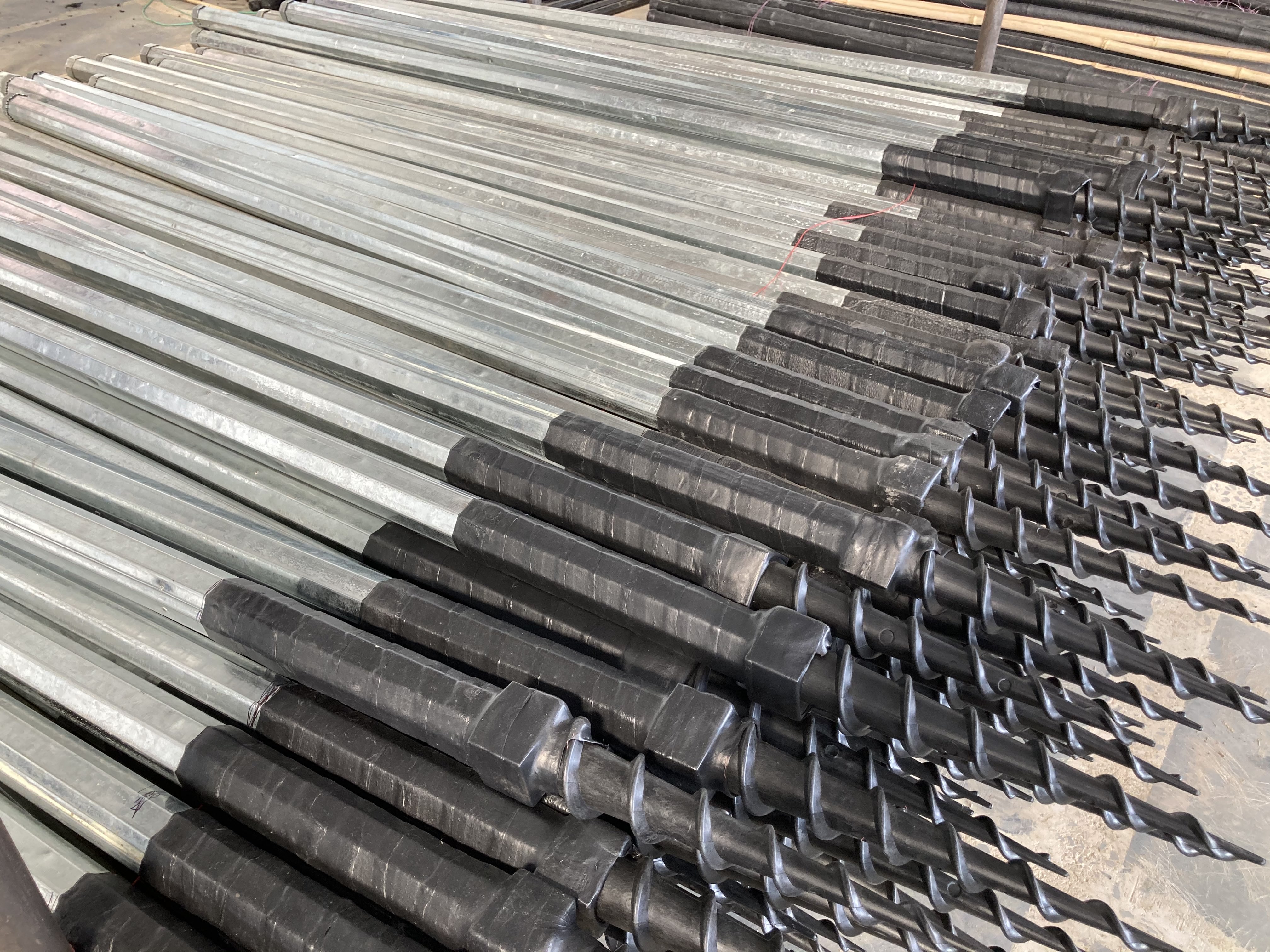

EACO STEEL RUDDER [BSUPOLE]

Our product “EACO STEEL RUDDER ” consists of a Galvanized Iron (GI) Sheet with special injected Polyurethane Foam material. The pole has been reinforced with bamboo – which has been proven to have 6 times the TENSILE strength of steel for certain applications. This solution provides tensile strength that can bear the forces of nature. We have also innovated a unique way to install the poles with a self-drilling solution – taking away the need for cement, water, grouting and heavy labour cost of installation. This saves valuable installation time & hassle of carrying grouting material to the site. Put together with a customized manufacturing process & tight QC checks, this product is poised to reduce total cost of Installation & Ownership (TCIO).