manufacturing process

Bamboo Sourcing

Bamboo Sourcing

We have selected eight spices of bamboo as per our product applications.

Transportaion

Transportaion

We transprot bamboos from different regions of india distance of 100 to 2200km. Our skill harvesting team ensure maturity and quality of raw bamboo.

Grading And Sorting

Grading And Sorting

We grade and sort bamboo pole as per product requirement with SLDW formula (spices length diameter wall thickness). Every variety gets a unique code like (25STI40M) which remains with it in all operations.

Cutting

Cutting

We cut the both end of Bamboo poles in proper shape.

Sizing

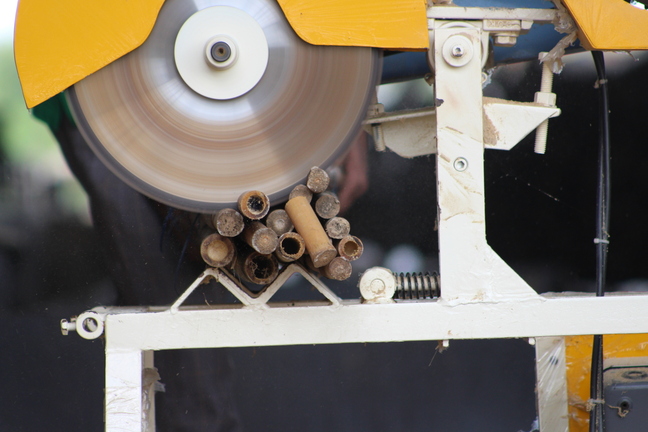

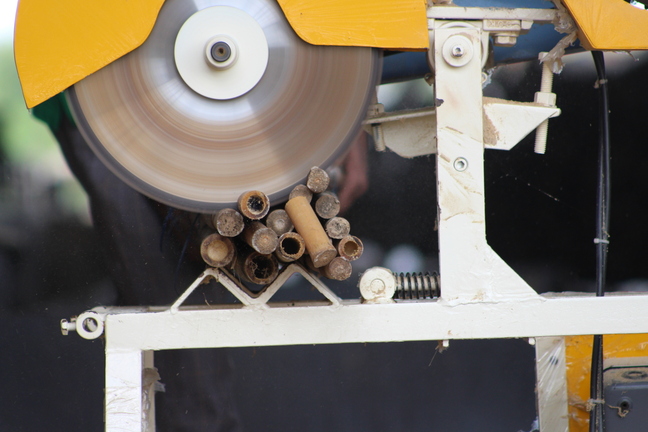

Sizing

We cut the bamboo pole in desired length with high accuracy cutting machines.

Knot Removing

Knot Removing

We transprot bamboos from different regions of india distance of 100 to 2200km. Our skill harvesting team ensure maturity and quality of raw bamboo.

Cleaning

Cleaning

We clean the outer surface of bamboo with wire brush and flap disc with Sodium Bicarbonate and water solution to remove the soil and other deposits.

Drilling

Drilling

We drill the raw bamboo in each inter node. It helps air ventilation for seasoning process.

seasoning

seasoning

We put raw bamboo poles in solar dry-based Polycarbonate Tunnel for seasoning with the use of hot air and thermal air ventilation/exhaust.

Oil Based Treatment

Oil Based Treatment

We Treatment is done by hot & cold dip and vaccum impregnation methods. Method is selected according to bamboo species. Each and every pore of bamboo has been filled with Treatment which protects bamboo from termite and other insect attacks.

seasoning After treatment

seasoning After treatment

We again put the bamboo in seasoning tunnel for treatment oil retention.

Straightening

Straightening

We overlay the mixture of Sodium Bicarbonate & musterd oil on bend bamboo and keep it under room tempreture for 6 hours. Then, we heat the bamboo with the use of wood fire and put it in wooden clamp and exert pressure in opposite direction of band to get straight position. Again, heat it to retain perfect straight position.

Stapling

Stapling

We staple bamboo poles and move them to feedingbay of coating plant.

Coating

Coating

We put the bamboos in HDPE coating plant for coating.

Cooling

Cooling

Water cooling system overlay the HDPE material properly bamboo poles.

Cutting

Cutting

We cut the coated bamboo poles in desired length manually or by machine.

Removing Joint Pin

Removing Joint Pin

We remove the joint pin from the bamboo poles with the help of instrument.

Capping

Capping

We fix the cap at the top of bamboo poles at capping point.

Fixing Ground Anchor

Fixing Ground Anchor

We fix the ground anchor which is made of ABS materials at the bottom of poles.

packaging

packaging

We fix the ground anchor which is made of ABS materials at the bottom of poles.

Bundling

Bundling

We take the bundle of finish products to packaging point for stretch wrapping.

Storage

Storage

We take the packed products from factory to store by Trolly toi dispatch.